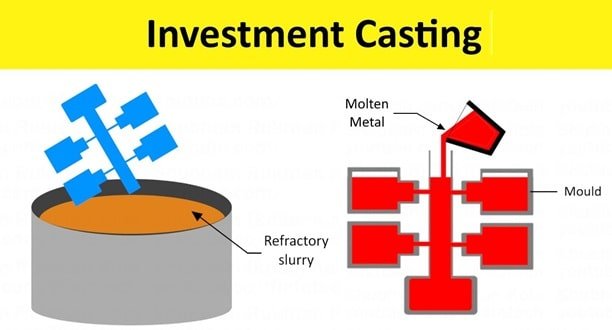

For those of you who don’t know, investment casting is actually one of the oldest techniques we humans know for metal casting which is an industrial process and it actually works or is based on lost-wax casting. All in all, it is a method where the metal is liquified and molded into whatever shape we want the final product to look like. It is as simple as that. Now, you might have already speculated that there are some obvious benefits to this method of metal casting, right? But what about the other side of things? Yeah, there are some less shiny side of things about this whole investment casting thing, and today we are gonna talk about that too. That’s because today’s post is all about Investment casting advantages and disadvantages, so yeah, here we go.

| Advantages | Disadvantages |

| Super Precise Stuff | Longer Production Time |

| High-Quality Surface Finish | Higher Cost for Low Volume |

| Tricky Shapes? No Problem! | Labor Intensity |

| Material Versatility | Limitations in Casting Large Parts |

| Big or Small, It Does It All | Complexity in Casting Cores |

| Saves You Money on Big Orders |

Advantages Of Investment Casting

Like always, why not begin this post with the benefits of investment casting, right?

1. Super Precise Stuff

Investment casting is really awesome for making parts super precise. This is super important in jobs where being exact is key. Think about making stuff for spaceships or medical tools where even a tiny bit off, and it’s a no-go. That’s why being this accurate is a big plus for investment casting.

2. Top-Notch Surface Looks

One of the coolest things about investment casting is how smooth and nice the surface turns out. This often means you don’t have to do extra work to make it look good. When you compare it to other ways of casting, investment casting can save you a bunch of time and effort in making things look perfect after they’re made.

3. Tricky Shapes? No Problem!

Casting really complex shapes with lots of details? That’s where investment casting shines. It lets you make parts without needing extra space in the design, so you’ve got more freedom to be really creative. Whether you’re working on parts with tricky cuts or stuff inside, investment casting can handle it all without breaking a sweat.

4. All Sorts of Materials Work

Here’s the cool part about investment casting: it’s like a one-size-fits-all for different metals. Think of steel, aluminum, and even bronze, this method handles them all. Why does that matter though? Well, it’s super handy for loads of different jobs in various industries. Whether a material melts easily or not, investment casting’s got it covered.

5. Big or Small, It Does It All

Need something tiny and detailed or something big and bulky? Investment casting can do both. It’s kinda amazing how it works for a whole bunch of sizes. And yeah, it’s not just about size. This method is super efficient, especially for the tricky, complex parts. That’s why lots of manufacturing folks prefer it, it’s really flexible and gets the job done well.

6. Saves You Money on Big Orders

Okay, let’s talk about saving some money. If you’re looking at making a bunch of stuff, investment casting is a pretty smart choice. Sure, setting it up at first might hit the wallet a bit, but if you’re making lots of items, it actually works out cheaper per piece. So, if you’re planning to produce a lot, this method is a real money-saver in the long run. It’s like buying in bulk, the more you get, the more you save!

Disadvantages Of Investment Casting

Alright, now onto the less shiny side of things when it comes to investment casting, ready for that? Here we go.

1. Takes a Bit Longer to Make Stuff

So, you know how investment casting has a bunch of steps? Yeah, that’s gonna stretch out how long it takes to get things done. If you’re racing against the clock on a project, this might throw a wrench in your plans. It’s like, you’ve got all these stages to go through, and each one adds a bit more time to the clock.

2. Costs More for Just a Few Pieces

Thinking about using investment casting for just a small batch of stuff? Heads up though, it might not be a good thing for your wallet, and that’s the truth. This method is really more about making loads of parts at once. The deal is, all the upfront cash you gotta put down spreads out better over a ton of parts rather than just a handful.

3. Needs a Lot of Hands-On Work

You see, investment casting is pretty hands-on. We’re talking skilled folks needed at every turn, and a lot of manual work. What does that mean for you? Well, more hands on deck equals more money spent on labor. This is especially true if you’ve got parts that need a lot of detail or are kinda complex. It’s like needing a whole team of chefs for a fancy dinner rather than just one for a simple meal. You see what we are trying to explain here?

4. Trouble with Big Stuff

You know, investment casting is pretty cool with its size range, but it is not a good method when we’re talking about really big parts. If you’ve got a project with some massive components, you might wanna look at other ways to do your casting. Just saying, it’s better to be in the know now than to hit a roadblock later, right?

5. When It Gets Too Complicated

So, here’s the thing about casting stuff that needs cores, especially the tiny hole kind, it’s tricky in investment casting. What this means is, you’ve got to think long and hard in the planning stage. Make sure you’re not backing yourself into a corner where investment casting won’t cut it. It’s all about getting ahead of the game and knowing your options.

Conclusion

That’ll do it. Now you know when or when not to use investment casting when dealing with metals, right? We tried our best to put out every benefit and negative of this method so that you can form a conclusion of your own, and we hope that we succeeded in that.

Santosh Kumar is a Professional SEO and Blogger, With the help of this blog he is trying to share top 10 lists, facts, entertainment news from India and all around the world.